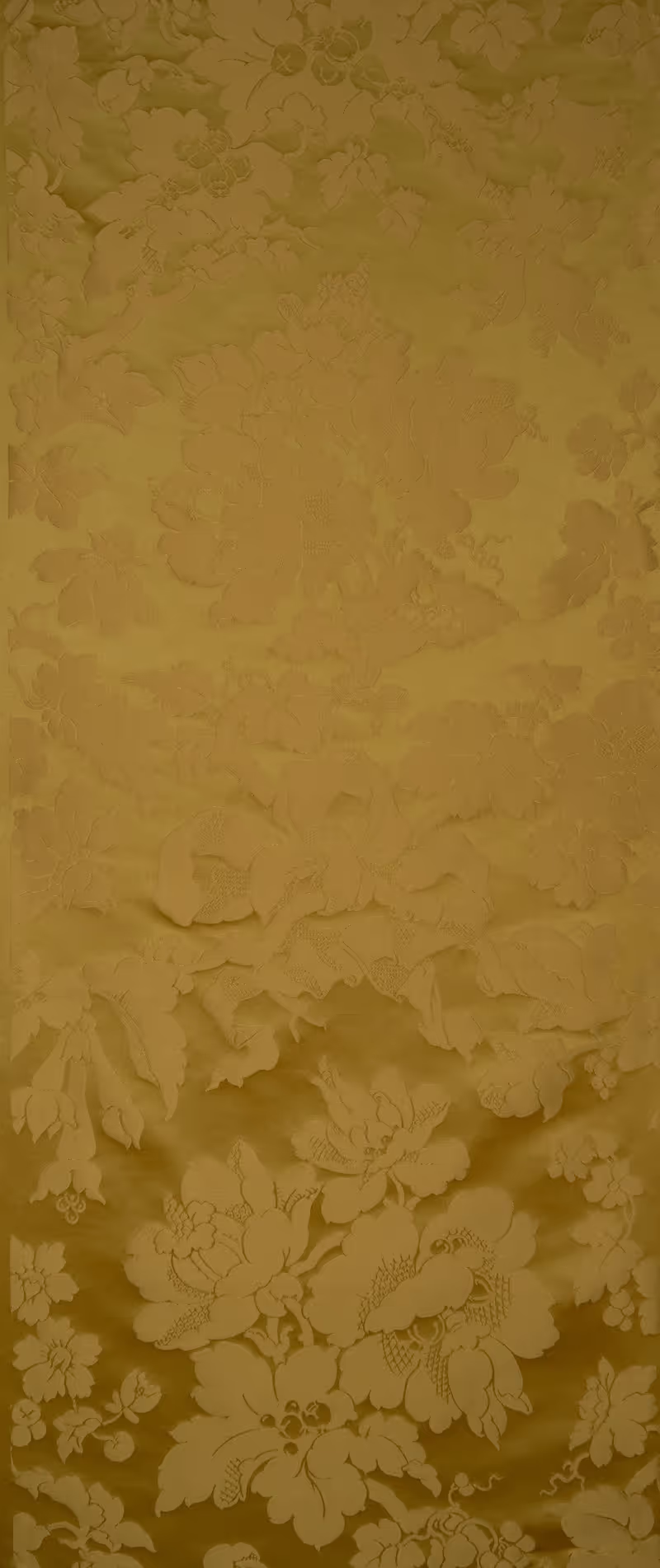

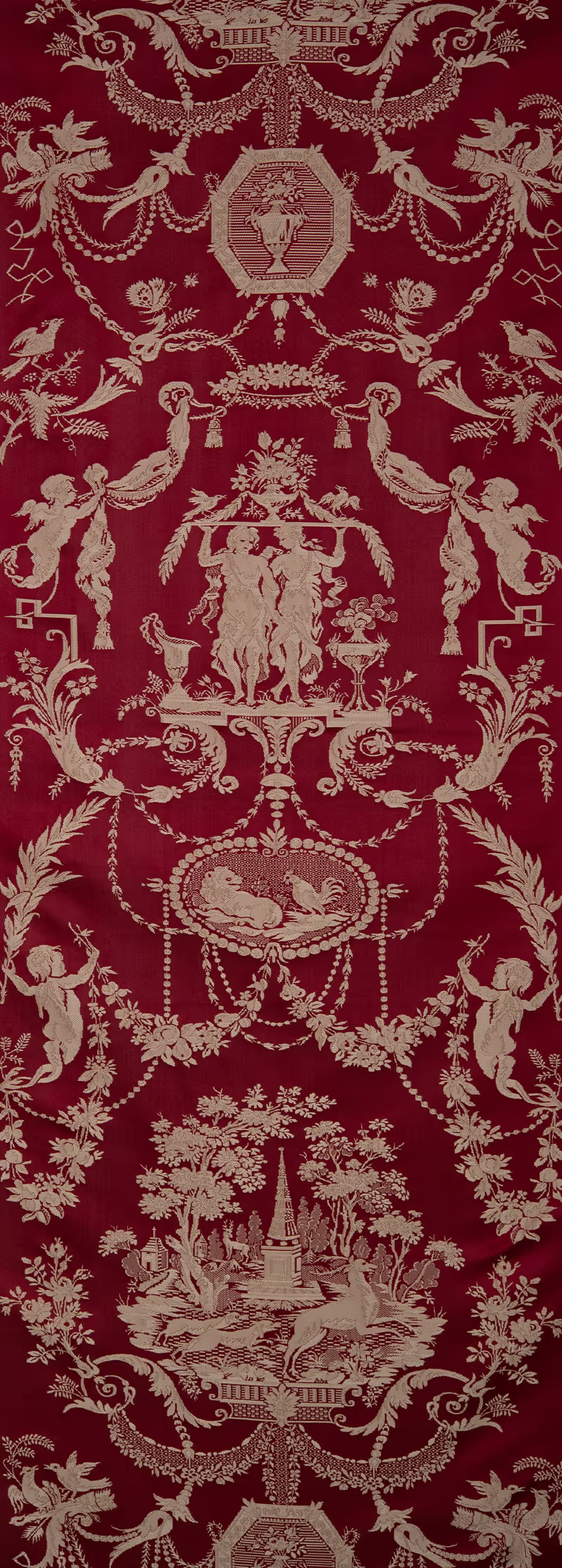

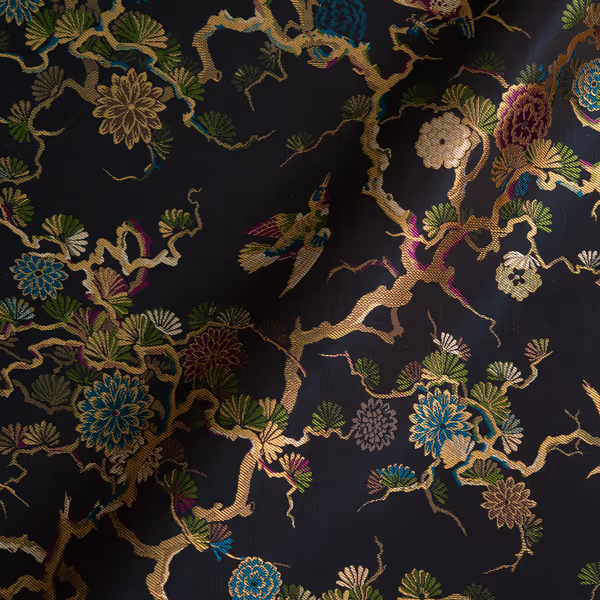

Between creativity and artisanal mastery, an incomparable Prelle signature

Since 1752

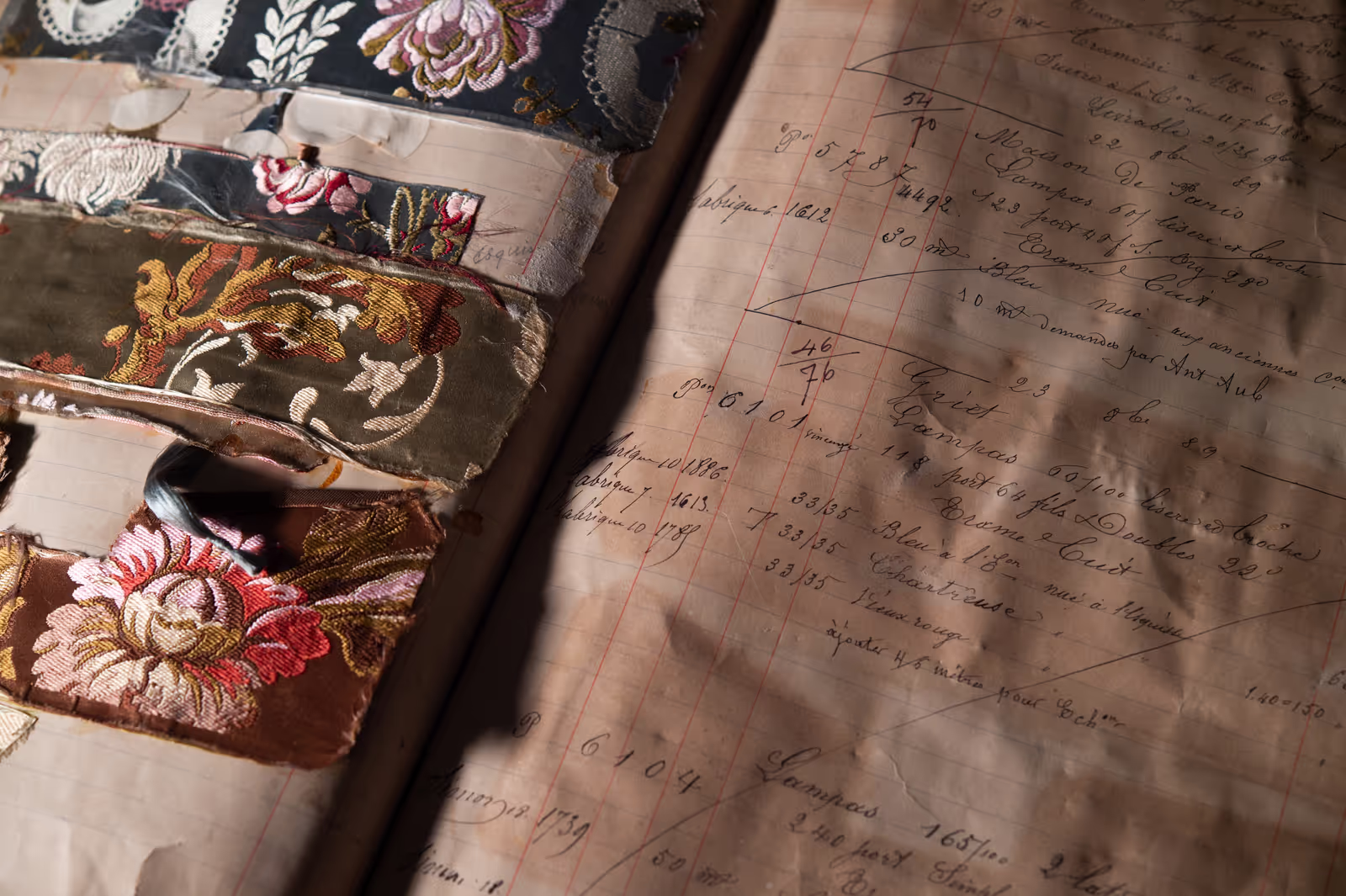

A family business for 9 generations, with ancestral expertise.

Prelle is one of the oldest Lyon manufacturers of furnishing fabrics today, and the only one that has remained a family business and continues to create and produce exclusively in France. It is the partnership of two families, Prelle and Verzier, both long-standing Canuts, that has allowed the traditional craft of silk working in Lyon to endure.

It is through numerous technical advances and the design of loom prototypes that the Prelle Manufacture continues to evolve over the years.

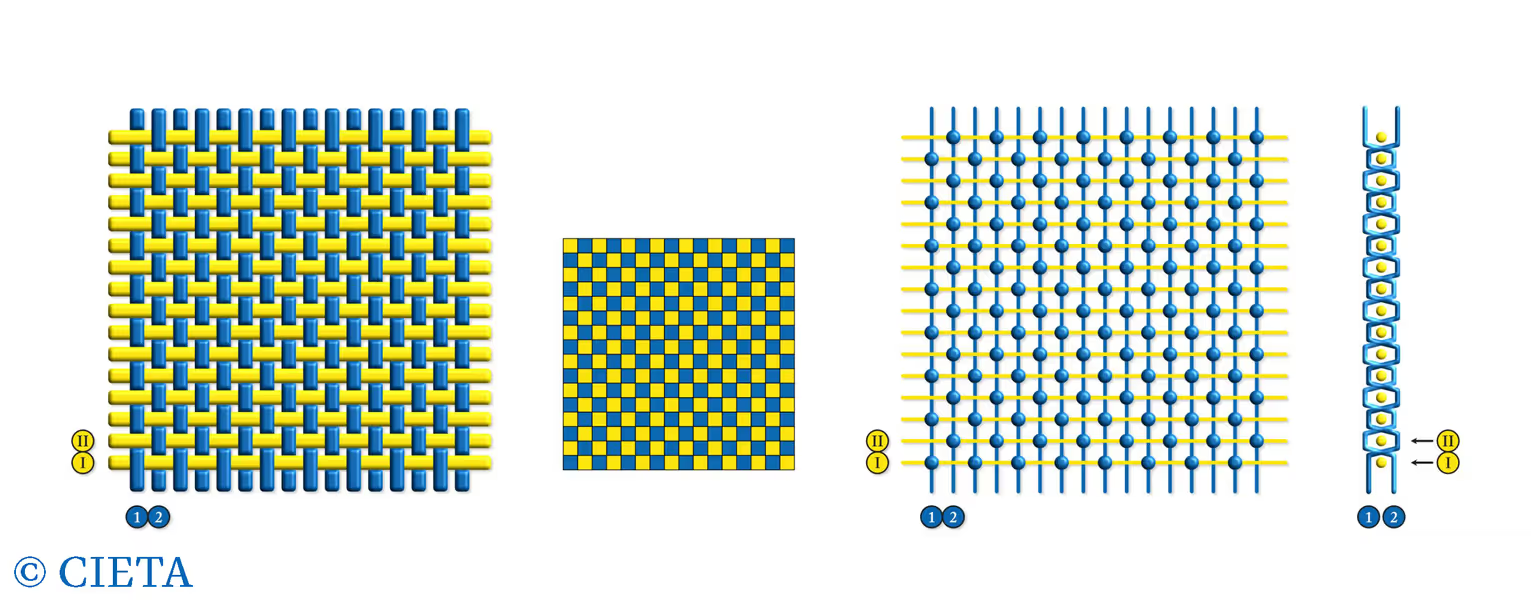

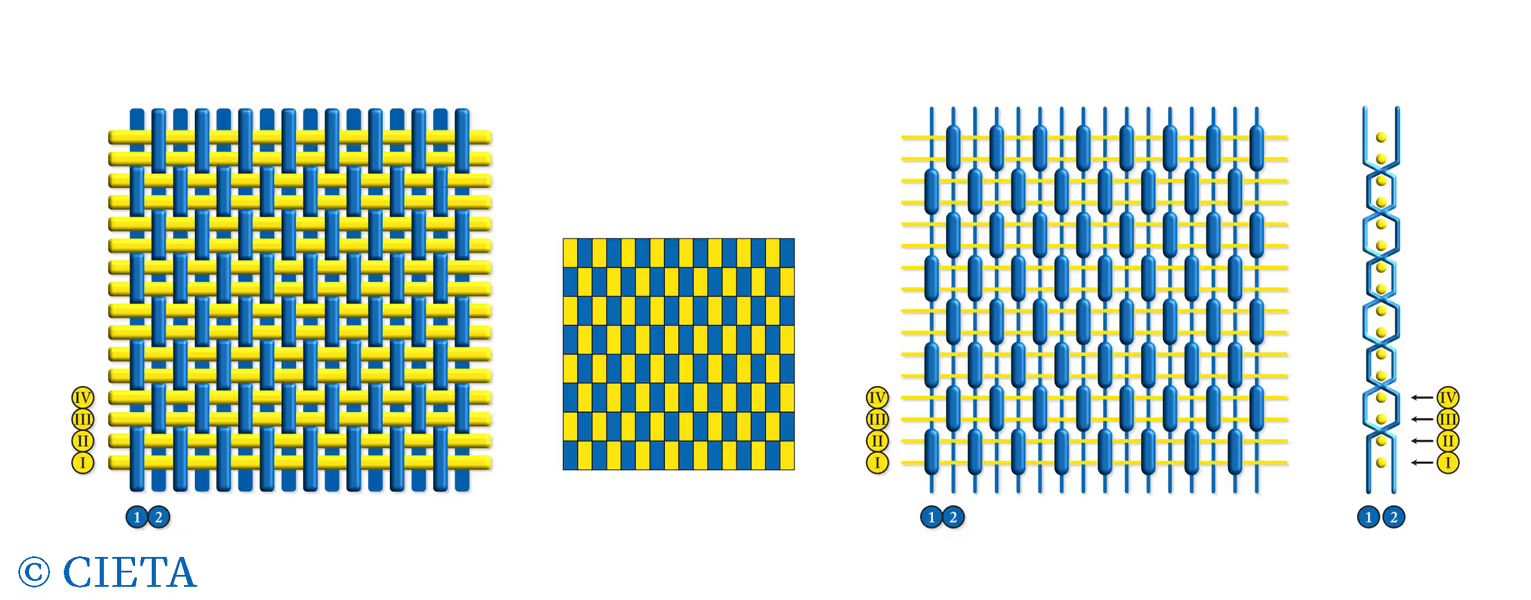

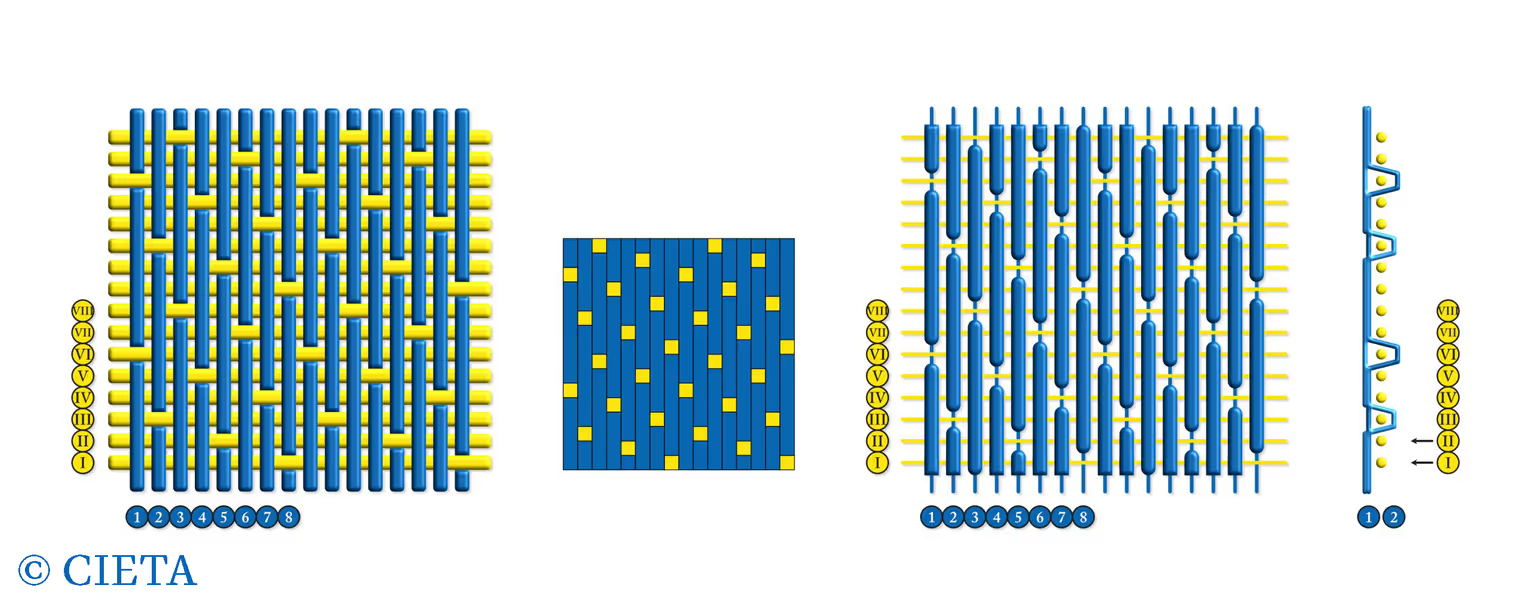

Our techniques

Spotlight on