Discover all the trades that make up the Prelle manufacture

A manufacture is more than fifteen areas of expertise in the heart of Lyon

The trades of the manufacture

From the conception of the design to the card cutting, rigging, thread handling, production organization... there are many steps before weaving to create a quality fabric.

Archivist

Preserves, organizes and brings to life the manufacture's extraordinary archive collection, spanning nearly three centuries of creation, establishing the essential link between historical commissions and present-day re-weavings that enable Prelle to faithfully reproduce the fabrics of the past.

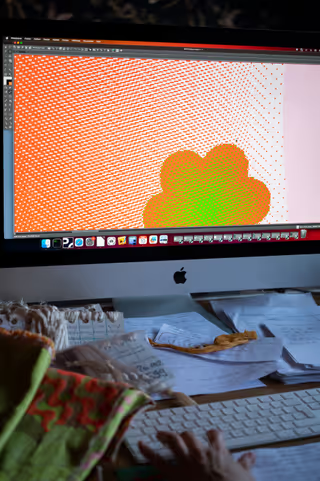

Design Studio

Translates artistic creations into technical instructions point by point, combining textile expertise and digital mastery to materialize each pattern on the loom.

Production Planning

Orchestrates the production flow by precisely planning each stage, from dyeing to weaving, ensuring deadlines are met while maintaining our standards of excellence.

Winder

Transforms kilograms of dyed silk into meters of uniform thread, winding them onto bobbins of equal weight and quantity, an essential step in preparing the warp.

Warper

Prepares the fabric warp by precisely assembling thousands of silk threads on the warping frame, creating the vertical sheet that forms the foundation of all weaving.

Tier / Knotter

Masters the delicate art of textile knotting to install new warps on the loom and repair each broken warp thread among tens of thousands, thus preserving the integrity and perfection of the fabric.

Weaver on Power Looms

Oversees the smooth operation of weaving on state-of-the-art electronic looms, ensuring impeccable quality of every centimeter of fabric produced.

Weaver on Hand Looms

Perpetuates ancestral techniques on 19th-century Jacquard looms, uniquely capable of weaving ciselé velvets and exceptional large brocades unattainable by mechanical means.

Fabric Inspector

Meticulously examines each woven fabric, identifying and correcting imperfections invisible to the untrained eye to guarantee the excellence our clients expect.

Production Manager

Coordinates all workshops and supervises the technical execution of orders, guardian of the transmission of savoir-faire and Prelle's manufacturing quality.

Cutting

Ensures precise cutting of fabrics while respecting pattern matching, ensuring that each ordered length is perfect. Ultimate guardian of the excellence of work accomplished, from warping to weaving, before the fabric reaches its recipient.